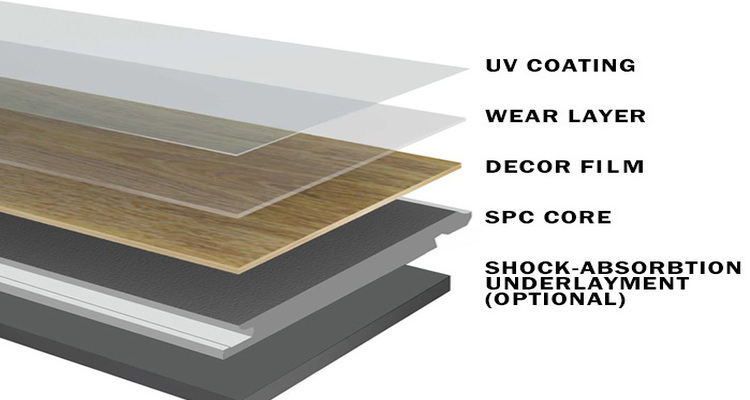

SPC flooring is luxury vinyl plank or tile flooring with a stone-plastic composite core. Also known as rigid core or engineered vinyl flooring, it’s manufactured in four or five layers, depending on whether the backing is foam or cork. The backing is often added for comfort and insulation.

Manufacturers produce the SPC core, typically from 3.2- to 7 millimeters thick, by combining limestone powder, polyvinyl chloride and stabilizers. SPC is thinner than typical WPC because stone is denser than wood. Owing to the limestone core, SPC floors are durable, with typical warranty periods running 25 years or so.

Structure of SPC Flooring

Advantages of SPC Flooring

Easy to install: SPC flooring boards snap together like laminate boards and float above the subfloor. No glue or nails required.

Durable: A wear layer protects the design layer, resisting scratches and damage from ultraviolet light.

Comfortable: Most SPC flooring planks and tiles feature an underlayment cushion for comfortable walking and some heat and sound insulation.

Lots of design choices: Designs mimic various types of hardwood and stone flooring, as well as geometric patterns reminiscent of old-style linoleum and vinyl sheet flooring.

Less expensive: SPC is generally more affordable.

How To Install SPC Flooring

Luxury vinyl flooring with an SPC core comes in planks or tiles that snap together to form a floating floor. Unlike earlier versions, most require no glue. They’re easy to assemble, even easier than laminate planks, because you can cut them by scoring with a knife and snapping. You only need a saw for cutting curves and notches.

SPC flooring can be installed over many other types of flooring, including hardwood, vinyl and some types of tile. The subfloor must be flat, however, so some preparation might be required first. An underlayment is also recommended if the product you install doesn’t have one. Finally, you’ll need to install baseboards to hold the flooring down.

浙公网安备号

浙公网安备号